Products and Processes

Prototype Production for Mass Production

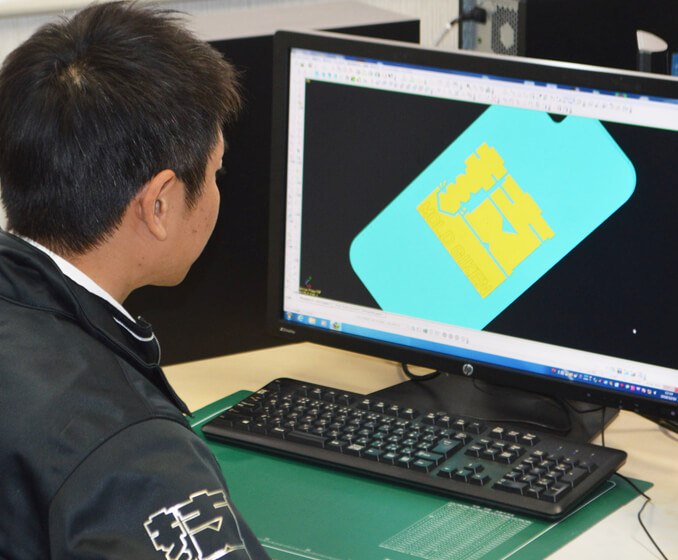

Mold and Jig Design and Production

Molds are finished by craftspeople with the help of 3D modeling and an MC.

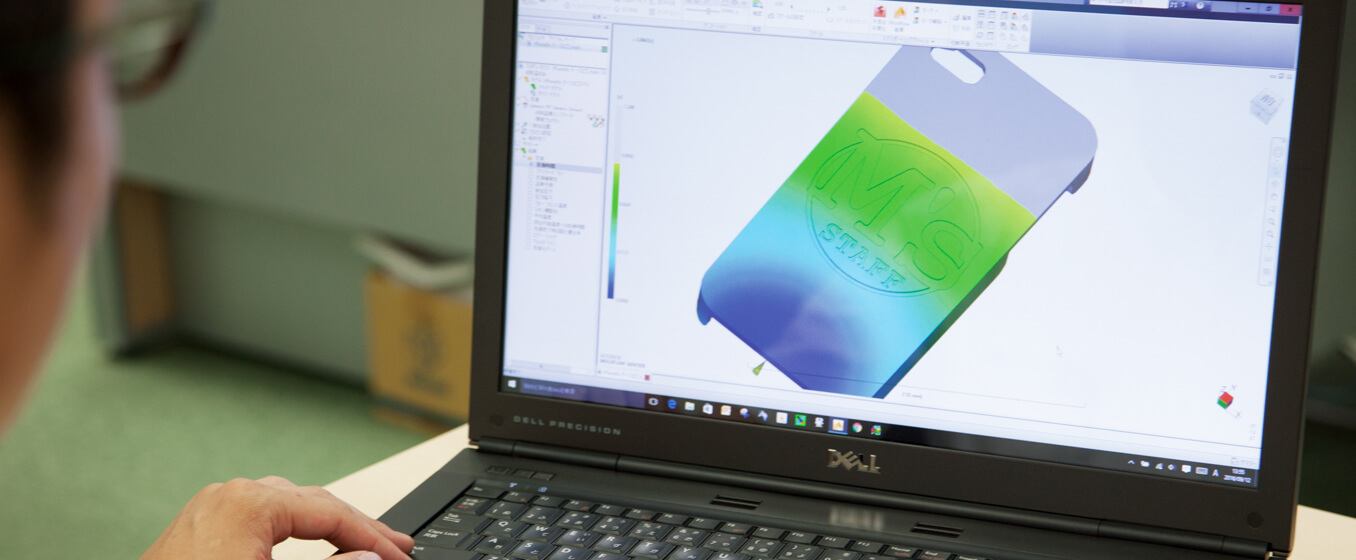

Flow Analysis

Flow analysis is used to solve mold problems, starting with the design stage.

Injection Molding

We are capable of handling a wide variety of molding materials.

Vibration Welding

We also produce jigs specifically for vibration welding.

Delivery (Quality Assurance)

Development-Support Prototype Production

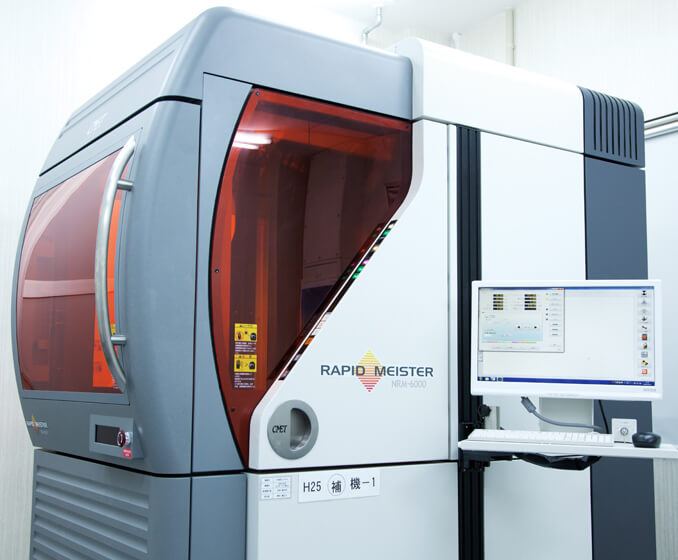

Stereolithography

We use a stereolithography system in the production of some products.

Vacuum Casting

Using stereolithography we also produce silicone rubber molds based on other products, and then use the molds to make cast products.

Hot Air Welding

Another advantage of MoldGiken is its proprietary resin welding technologies.

Cut Resin Products

We produce cut resin products, which have been cut and welded.